Understanding the Properties of Fly Ash for Efficient Separation

Fly Ash is an end-product obtained after the coal combustion process. It is a heterogeneous product used in various applications, like dams, landfills, mines, and concrete.

This fine gray-colored powder contains different impurities, which must be separated for efficient beneficiation. It may include spherical glassy particles with flue gasses and pozzolanic materials forming cement-like substances. In addition to this, this substance may contain other contaminants of varying nature.

It is essential to learn about the various properties of fly ash to ensure you achieve efficient beneficiation and a high-quality end product. Read this post to explore all the properties of fly ash.

How is Fly Ash Formed?

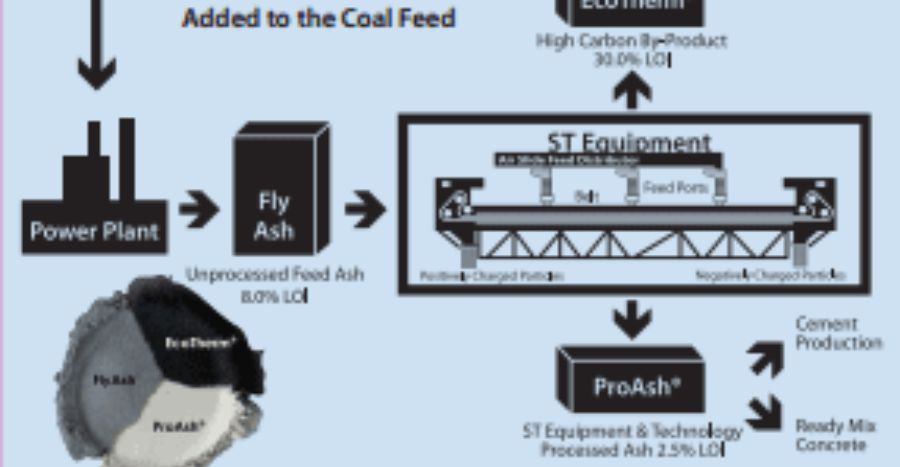

Fly Ash originates during the process of coal combustion in a boiler. This material solidifies during the suspension of exhaust gasses and gathers in filter bags or electrostatic fly ash separation equipment.

These particles are spherical in shape and vary in size from 0.5 um to 100 um. Silicon Dioxide, Aluminum oxide, and Iron oxide are the various substances included in this material. The silicon dioxide can be amorphous or crystalline, which makes it hazardous, pointed, and sharp.

During the retention time of 3-10 seconds, coal is burnt, and non-coal particles remain partial in their original form or shape. The bloating glass melts, resulting in hollow spherical particles known as cenospheres.

The boiler’s oxygen regimes and temperatures differ, making the fly ash formation process complex. But with consistent monitoring and understanding of its properties, it is possible to obtain premium quality substances.

Physical Properties of Fly Ash

Fly Ash contains fine particles in powdered form, predominantly of spherical shape. These particles are hollow, solid, or amorphous in nature.

The specific gravity of coal ashes is around 2.0 but differs to some extent, ranging from 1.6 to 3.1. The variation is because of distinct factors, like gradation, chemical composition, and particle shape.

This material can be sandy silt or vice versa based on the grain size. It has a big specific surface area and low density. The color of fly ash is influenced by the portion of iron and unburned carbon in it. The color can vary from deep red and orange to yellow, white, and brown. The particle size of fly ash ranges from 10 to 100 microns.

Chemical Properties of Fly Ash

The chemical properties of fly ash depend on the coal burnt and the process used for storage and handling. Based on the chemical properties, this substance can be of four types, each of which differs in terms of its chemical composition, geological origin, ash content, and heating value.

The four kinds of coal are bituminous, anthracite, lignite, and sub-bituminous. The main components of bituminous fly ash are alumina, silica, calcium, and iron oxide, with distinct amounts of carbon estimated by the ignition loss.

Bigger magnesium oxide and calcium concentrations with limited percentages of iron oxide and silica characterize sub-bituminous and lignite. Also, it has a lower content of carbon in comparison to bituminous fly ash.

The anthracite coal is another type burned in utility boilers. Hence, this type of fly ash has a small amount of anthracite. The sub-bituminous and lignite fly ash has a greater calcium oxide content and lower ignition loss than the bituminous coal fly ash.

Sub-bituminous and lignite fly ash may have a bigger concentration of sulfate compounds in comparison to coal fly ash.

Classification or Types of Fly Ash

Fly Ash is classified using different codes.

· Fly Ash Types as Per IS Codes

Grade I – The grade I Fly Ash is obtained from bituminous coal with fractions Si)2+AI203+Fe203 higher than 70%.

Grade II – The grade II Fly Ash is obtained from lignite coal having fractions as SiO2+ AI203 + Fe203 higher than 50%.

· Fly Ash Type as Per the American Society for Testing and Materials

This is another form of coal, and the chemical analysis is classified into distinct types:

Type F – The Fly Ash is obtained from combusting anthracite or bituminous coal, with 10% lower Ca0 and pozzolanic properties.

Type C –Type C fly ash is produced from the combustion of sub-bituminous or lignite coals. It contains CaO greater than 10% and holds a cementitious nature and pozzolanic properties.

· Fly Ash Based on the Boiler Mechanism

LT or Low-Temperature Fly Ash – It is generated with coal combustion at a temperature below 900 Degrees Celsius.

HT or High-Temperature Fly Ash is produced from coal combustion at a temperature lower than 1000 Degrees Celsius.

Different Types of Particle Sizes

Fly Ash holds various particle types with varied reactivity and origins. Usually, five kinds of particles are as follows.

Type 1 contains crystalline particles with an original round and sharp-edged shape. This type is not influenced by thermal impact morphology.

Type 2 – Sheeted structure, sintered particles, dewatered clays, and high inner surface are the main traits of this type of fly ash.

Type 3 – The type 3 fly ash particles hold a spherical, solid, filed, or hollow shape. These are molten minerals with Fe, Ca, and Silica Alumina.

Type 4 – It holds an inert nature with new crystalline phases and mullite.

Type 5 – It is the original shaped substance with a highly porous, sponge-like nature and high concentration of unburnt carbon or coke.

Assessing Fly Ash for Beneficiation

For fly ash beneficiation, it is vital to understand that each type has specific properties and depends on numerous factors. In general, fly ash quality is highly complex. However, knowing the kind of coal, loading factor, boiler, and other aspects gives a fair idea of the quality and quantity to expect.

You can make a good prediction of its quality by considering its properties. If you need further assistance with this substance or want to achieve quality outcomes, you may consider using Steqtech’s fly ash separation equipment. We offer the finest equipment to help you gain quality results useful for numerous commercial applications. Contact us to explore more about our machine and services.